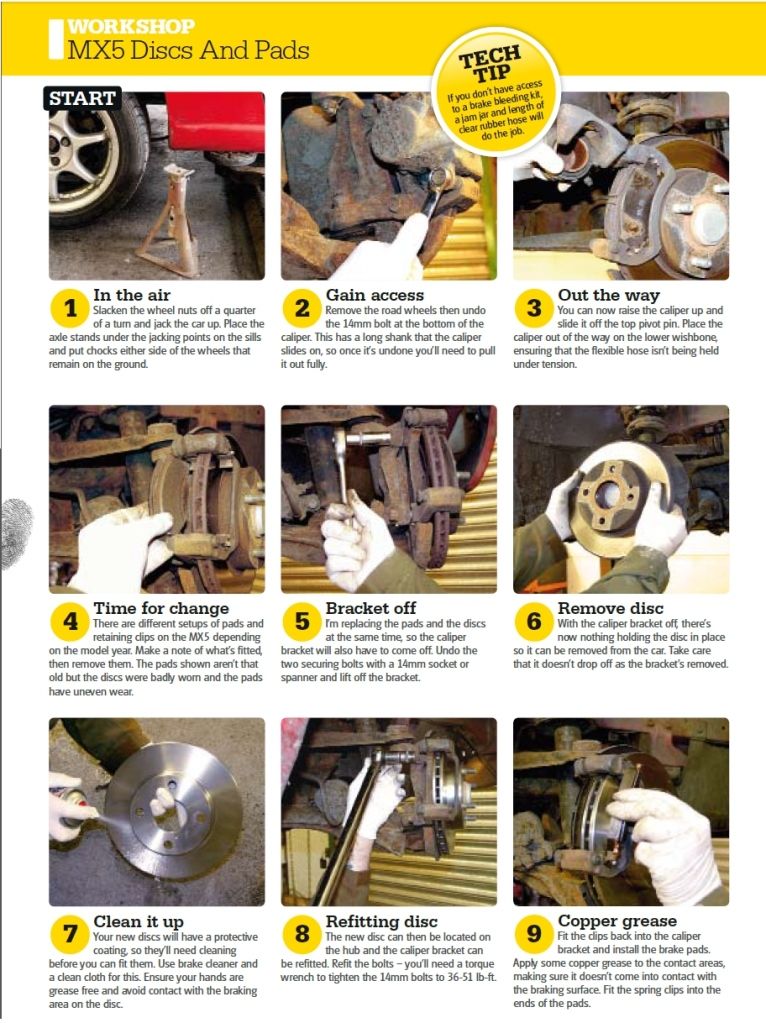

Aprovecho el antiguo tutorial (que sigue ahí abajo) por este mucho más esquemático, con mejores fotos y además cambiando los discos.

Como leeréis y os confirmo, TODO esto se consigue con la 'friolera' de una única llave vaso del 14...

(Con esa del 14 y otra del 10 desmontas medio coche. De verdad)

Las fotos son grandes pero merece la pena para leerlo bien. Si alguien se pierde con el idioma que lo diga que traducimos.

Adivinad que me toca este domingo

Información extraída de

http://www.mx5oc.co.uk/forum/forums/t/831.aspx Changing the brake pads on the ‘5 is one of the simplest "major" services you yourself can tackle. The following writeup covers the basics of removing and replacing the front and rear brake pads on a 1993 Mx5. It applies to all Mk1 cars

The entire job can be done entirely by ones self in an afternoon. It took me less than 3 hours, which included taking the pictures, making notes etc.

This document will cover both front and rear pad replacement.

Before beginning this project, make sure you have sufficient light, time and tools. Much of what you will be doing is straightforward, but attempting to find a small clip or spring in the dark would probably be quite difficult.

For starters, let's go over the minimum tools you will need. You will need a jack, four jackstands (two minimum), wheel nut socket, metric spanners (10mm and 14mm minimum), a 4mm hex key, a large pair of channel-lock pliers, sturdy string, anti-squeal compound, high-temp caliper grease, and the replacement pads.

Fronts:

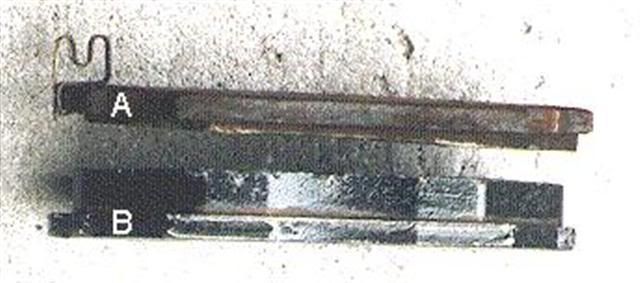

Since the front brakes do the majority of the braking, they tend to wear out first. (Check out pad 'A' in this picture to see what I mean)

If you hear a profound squeal when applying the brakes, you have likely worn your front pads down to the point where the "squealers" are contacting the rotor. In my case, I had worn the pads so low that the "squealers" were coming in contact with the rotors all the time. If you have reached the point I did where the "squealers" make noise all the time, you should attend to your brakes as soon as possible.

To begin removal and replacement of the front pads, securely raise the front of the car and remove both front wheels. Once the wheels are removed, re-screw at least 2 wheel nuts back on the wheel studs. This will insure that the disc stays in place during our installation.

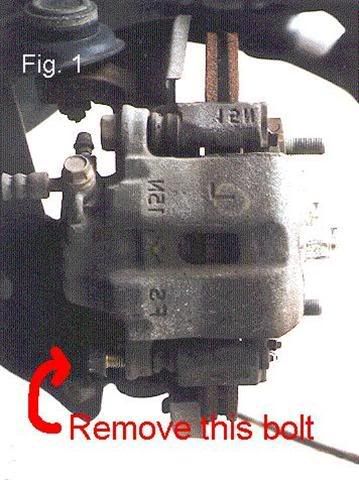

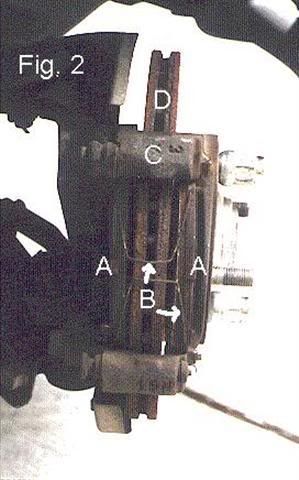

This picture shows the front brake caliper.

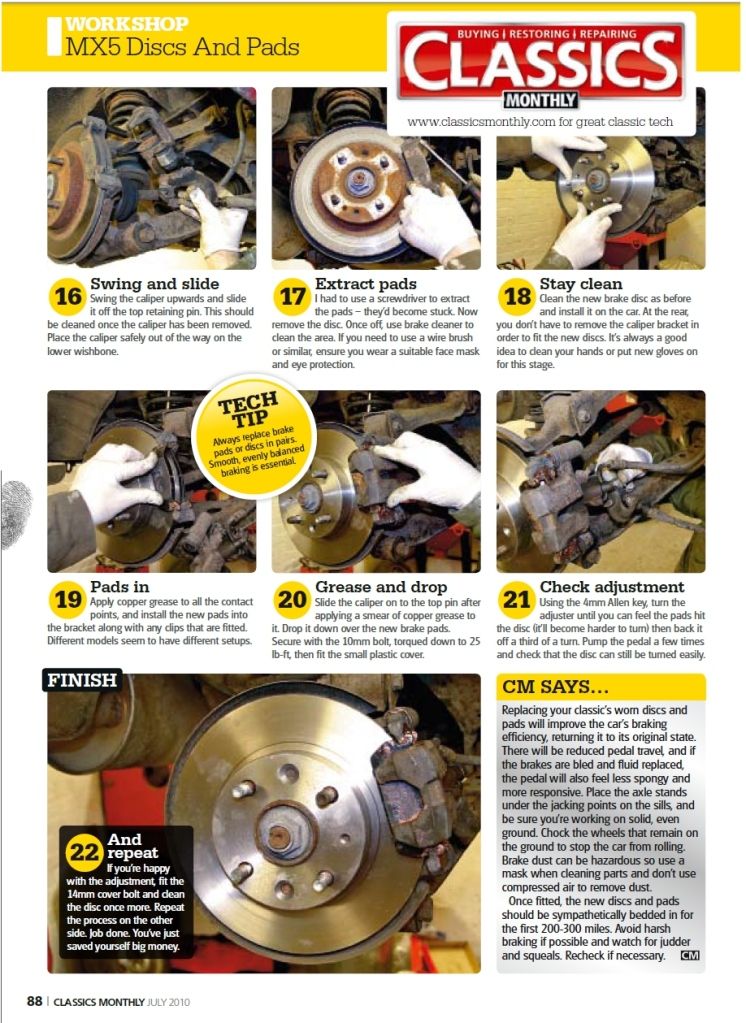

Remove the lower caliper bolt (arrow). Once this bolt is removed, the entire caliper can be tilted up on the axis of the upper caliper bolt. Use the string to tie the caliper up out of the way. This picture shows what you will find underneath the caliper (the caliper was removed for the picture).

The letters A correspond to the brake pads, the letter B to the springs, the letter C to the frame, and the letter D to the rotor. With the caliper up and out of the way, open the pads (A) up enough to remove the springs (B) from the pads. With the springs removed, the pads can be lifted out of the frame.

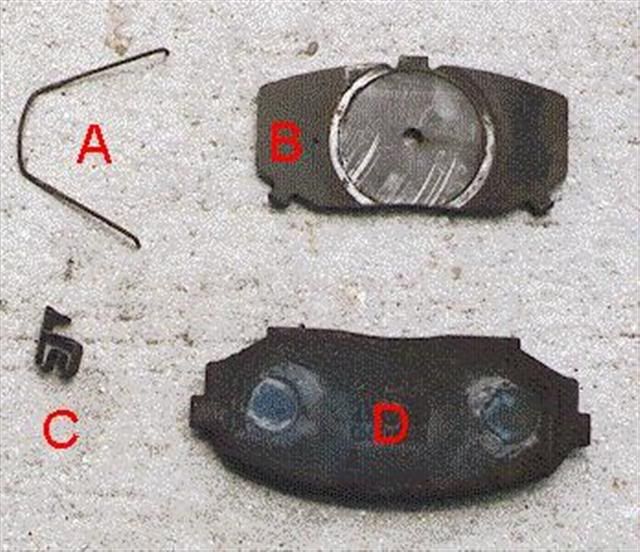

Now would be a good time to discuss theanatomy of a brake pad.

Letter A shows the front spring, letter B shows the front shim, letter C shows the front "squealer", and letter D shows the front pad. If you will be installing OEM Mazda replacement pads, check to make sure you have new springs, shims and squealers. If you will be installing aftermarket pads, you will likely need to save your old springs, shims and squealers. The squealers should slip right off the old pads. To remove the shims, carefully pop them off the old pads - a flat-bladed screwdriver might be necessary here.

Ok, now with the old pads removed, we are now ready to install our new pads. Installation is pretty much the reverse of what we've just done. If you are using aftermarket pads, apply some anti-squeal compound to the back of the pad before cliping the shims back on. Once the anti-squeal has had a chance to set, clip the shims on. Finally, slip the squealers back on. Now that you have the complete OEM pads ready, they just silde back into the caliper frame. Figure 3 shows my aftermarket pads. Note that the pads I used (Mintex Silver Line) did not use the OEM springs to retract the pads off the rotors. I was initially worried about the pads rubbing against the rotors, but after several years and many miles I have not had any problems.

With the new pads back in the frame, all that remains is to retract the caliper piston and bolt the caliper back on. To retract the FRONT caliper piston, first open the cap on the brake master cylinder. If you aren't sure what the master cylinder looks like,here's a picture.

Depending on how full your master cylinder is, you may need to take some brake fluid out of it. When you retract the pistons on all 4 brakes, you will likely overflow the master cylinder so it's a good idea to keep check on the fluid level after each caliper is done. With the master cylinder cap open, go back to the caliper and hold one of the old brake pads against the piston. Take the channel lock pliers and squeeze the old pad against the piston, pushing the piston back into the caliper. Once the piston is back in the caliper, you should be able to lower the caliper back over the new pads. Once the caliper is back down on the frame, all that remains is to add a liberal amount of high-temp brake caliper grease to the lower caliper pin bolt and bolt the caliper back together. That's it! Now, repeat the same procedure for the remaining front side.

Rears:

Replacing the rear pads is equally as simple as the front pads. The main difference is in retracting the rear caliper pistons. Note: Improperly retracting the rear caliper pistons could result in caliper failure and costly repairs. With that out of the way, let's begin.

Remember that once the rear wheels are removed, you will need to tighten down the rear rotors with a couple of wheel nuts. This must be done to correctly adjust the rear brakes.

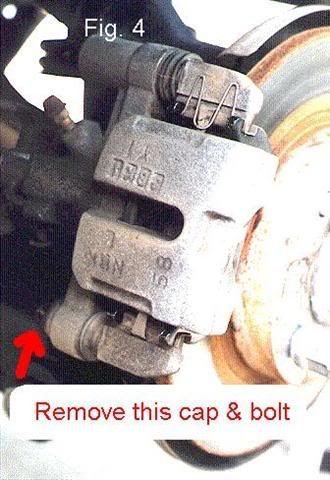

The first step with the rear brake pads is to retract the caliper piston. On the inside of the caliper is a 14mm bolt that acts as a cover for the manual adjustment screw. See pictures.

An easy way to find this bolt is to follow the brake hose to the caliper. There you will see two 14mm bolts next to each other. The one that covers the manual adjustment screw is the one next to the one that bolts the brake hose to the caliper. Remove this bolt and use the 4mm hex key to back the piston into the caliper. Don't forget to have the master cylinder cap open and keep an eye on the fluid level. This picture

Shows the rear brake assembly. In order to unbolt the rear caliper, first you must pull a black plastic cap off the lower caliper pin bolt head. With the cap off, you can now unbolt the lower caliper pin bolt and pull (and tie) the caliper up out of the way.

With the exception of the 'M' shaped retractor spring, the front and rear disassembly is identical. Remember if you are using aftermarket pads that you will need to re-use the shims and springs. With the rears though, the 'M' shaped spring should be usable on most (if not all) brands of pads. Also don't be surprised if the upper guide falls off the frame. Simply hold it in place while you slide the rear pads back in.

Once you have prepared the new pads for replacement, you can slide them back into place. This picture

Shows the new pads in place. You are now ready to lower the brake caliper back down over the frame. I waited until after I bolted the caliper back in place to clip the springs on. It just seemed easier. With the caliper back down on the frame, apply a liberal amount of high-temp brake caliper grease to the caliper pin bolt and bolt the caliper back in place.

All that remains now is to manually adjust the rear brakes. Slowly spin the rear rotor while you are turning the rear brake adjustment screw. Just at the point where the pads contact the rotor, back the adjustment screw off a tad (1/3 turn should be enough).

Repeat the above steps for the other side and you will be done with your brake job. Congratulations! Now it's time to go for a short test ride around the block. Don't forget to check the fluid level in the brake master cylinder (and tighten the cap). Make sure wherever you go that you test the brakes thoroughly on level ground before you head out in traffic. Once you are satisfied with your work you are ready to return to the road. During the break-in period for the new pads (a good 100 miles or so) try to keep your brakes from getting too hot. Make gentle stops and avoid long stops from high speeds. A good break-in will result in solid (and quiet) brake performance through the life of the pads.